Examples

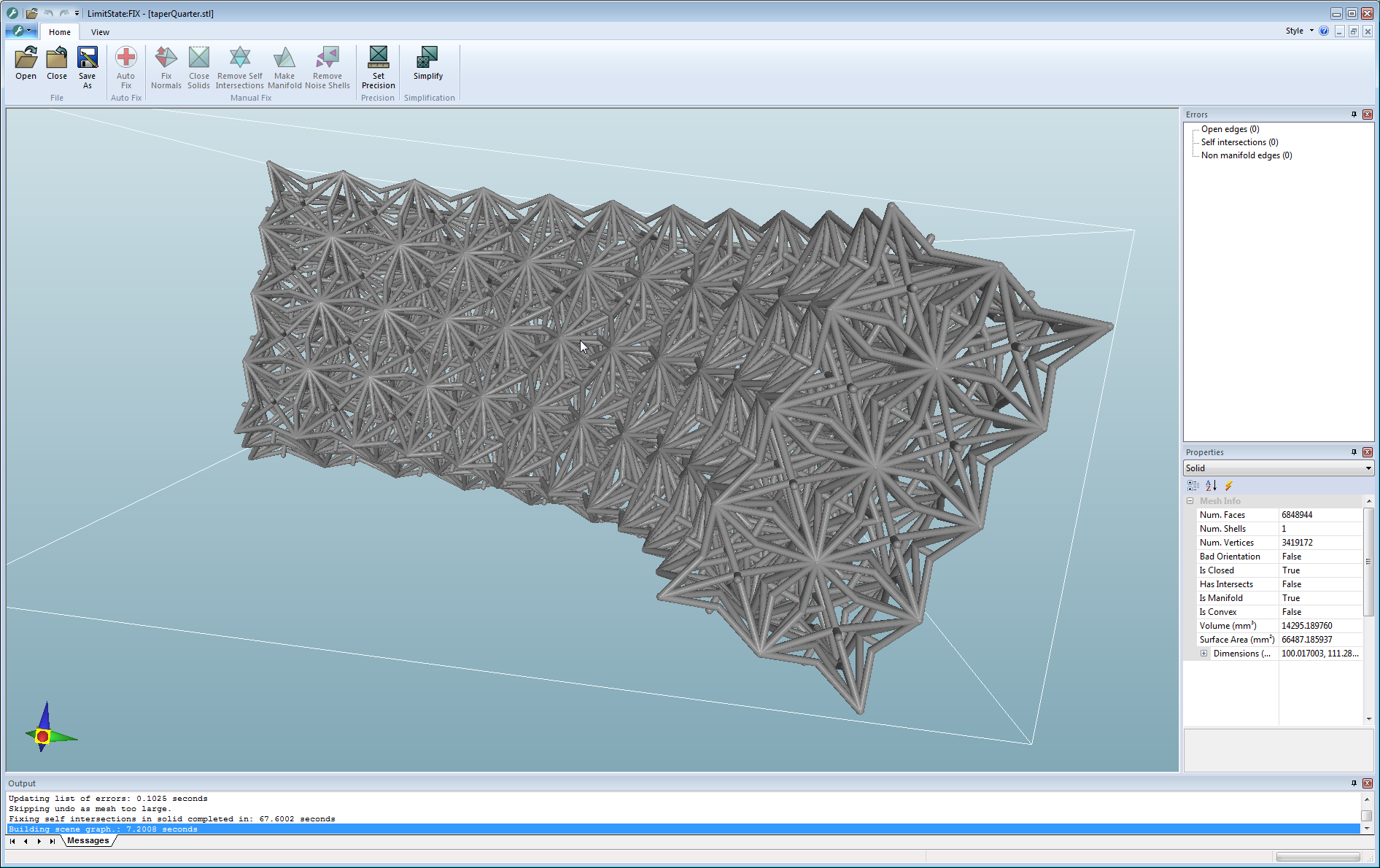

3D model of complex aerospace lattice using auextic materials

This model is an excellent example of the kind of complex models that LimitState:FIX can optimise, which other tools will not be able to support.

Produced and printed by the Mercury Centre for an aerospace client it is a lattice design made from advanced materials with special properties. Specifically it is an “auxetic” material - which means that it gets fatter rather than thinner when stretched. This makes it both very low-mass, and able to absorb enormous force, so auxetic materials are very useful in aerospace, automobiles, defence and many other fields.

These kinds of materials are useful to print in 3D for both production and prototyping, but the models can be extremely difficult to produce and print. LimitState:FIX is uniquely suited to fixing these kinds of complex models.

The Mercury Centre is a well known advanced manufacturing technology development organization within Sheffield University’s Department of Materials Science and Engineering.

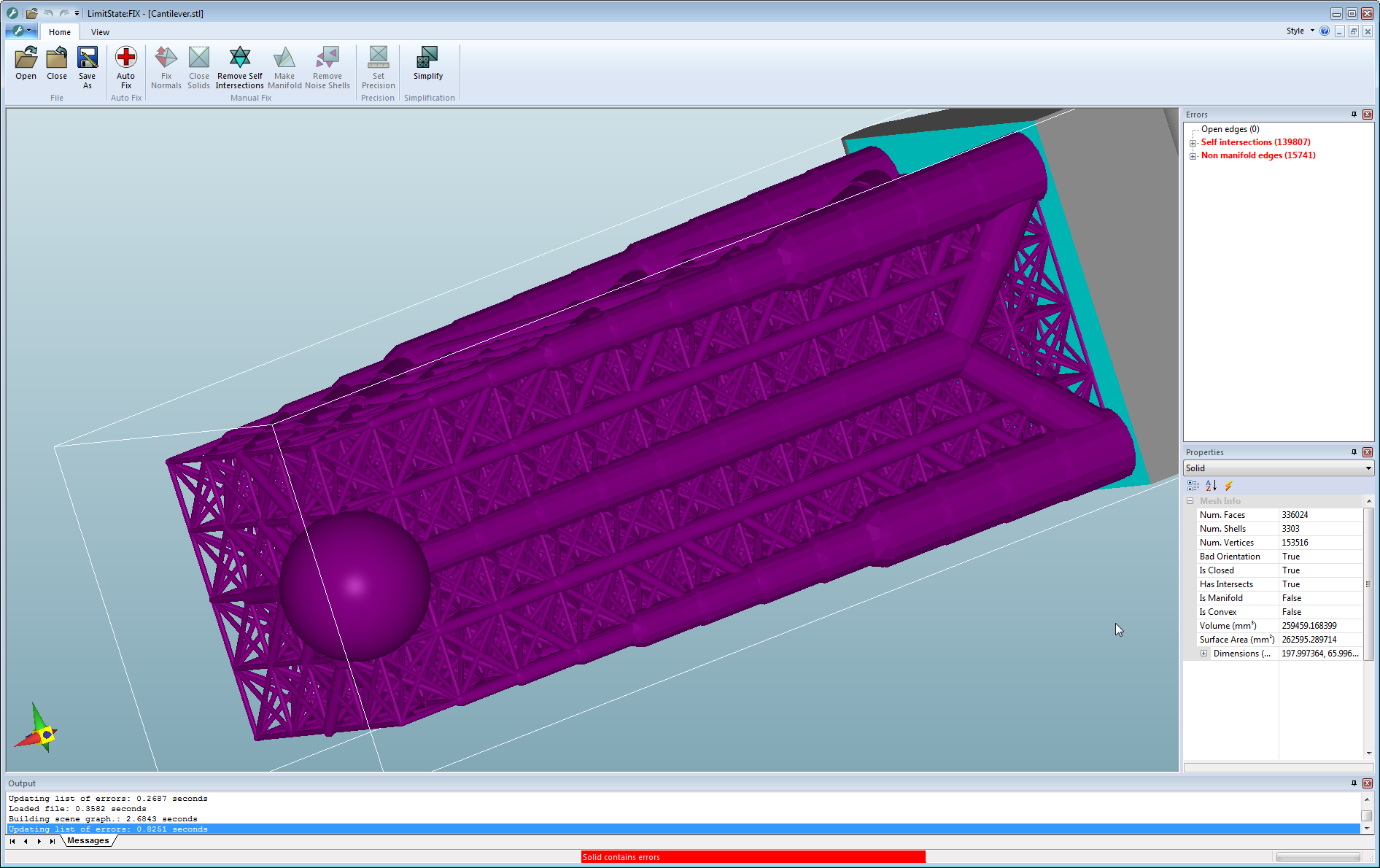

Complex cantilever for automobile chassis

This is another highly complex model where LimitState:FIX will save enormous time in the production and print process. It is a prototype chassis component using advanced design and materials to reduce weight and would typically be used for motor-sports applications. The weight-reducing design would be very difficult to produce with traditional manufacturing methods.

This is exactly the kind of engineering design work that professional 3D printers are doing, for prototyping, product development, just-in-time additive manufacturing and architecture. LimitState:FIX will therefore save enormous time and effort for the core of the professional 3D market. These kinds of lattices are complex, and the models are very difficult to check and fix by hand. LimiState:FIX’s automated fixing process is very accurate and effective and most software is not optimised for this kind of work. This is very much a benefit of using the Polygonica technology.

The original model had 139,807 self intersections, and 15,741 non-manifold edges. These would have been impossible to fix by hand - but more importantly, no other tool was able to fix these issues. The design could only have been printed using LimitState:FIX. Many other professional 3D print organisations will be facing similar issues, and will benefit from LimitState:FIX.

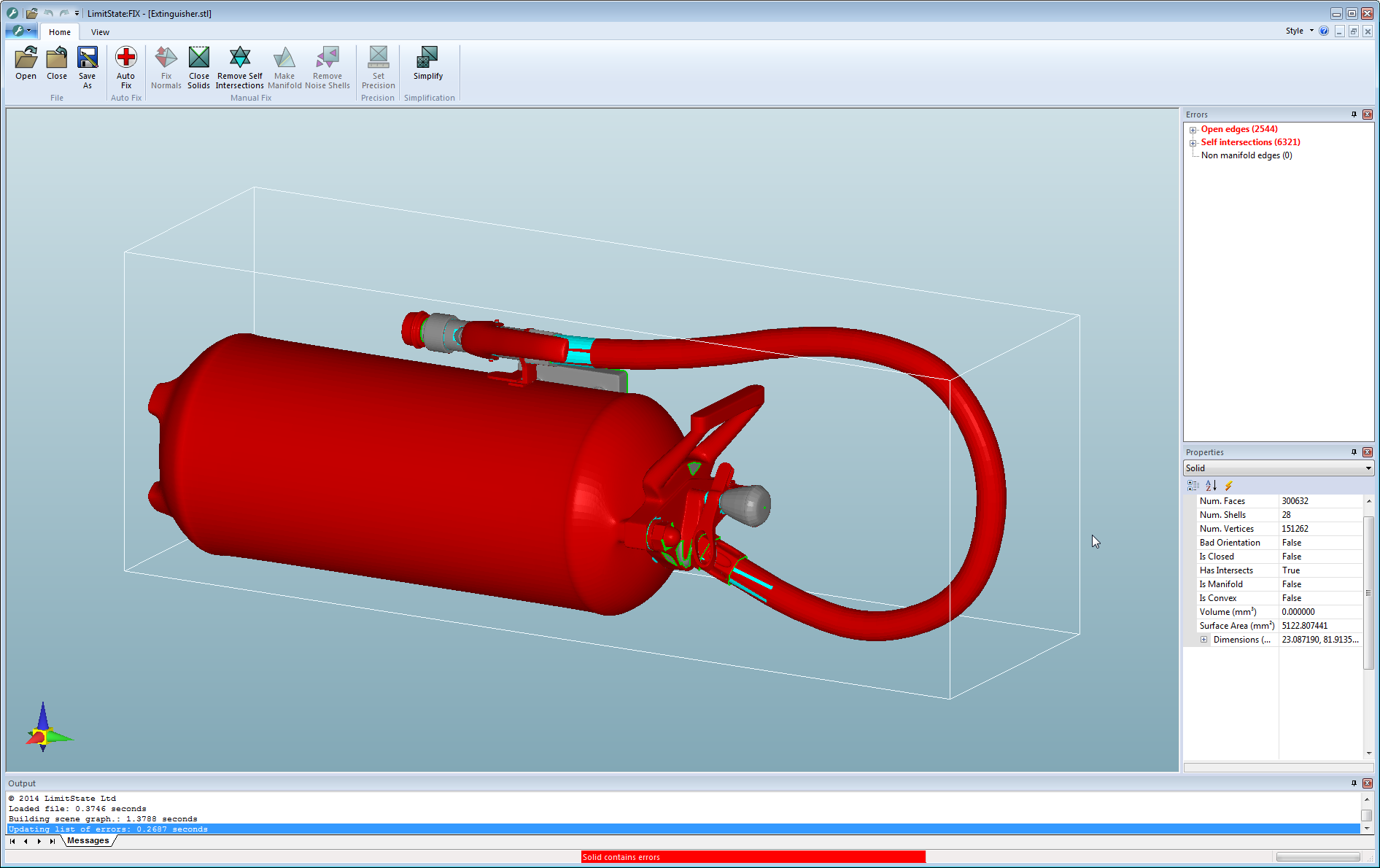

Fire extinguisher

This is a more familiar 3D design, of a fire extinguisher. Issues are highlighted in red, and there are many in this model - 2,544 open edges and 6,321 self intersections. Although the model looks right, it wouldn’t print, and it would take a very long time to fix all the problems. LimitState:FIX will automatically resolve all the issues with this model in seconds.